When working with concrete , there are several main requirements:

proper pouring of the concrete mixture, which consists of observing the necessary proportions of the components during mixing, as well as suitable weather conditions throughout the process;

proper pouring of the concrete mixture, which consists of observing the necessary proportions of the components during mixing, as well as suitable weather conditions throughout the process;- proper operation of concrete surfaces, including their hardening and any other necessary care in the future.

Working in normal weather conditions, observing all the proportions of the components of the concrete mixture, an additional necessary step in pouring concrete is just coating the surface with special reinforcing compounds to increase the wear resistance and strength of concrete surfaces. If the mixture lacks fluidity or concrete is poured at an air temperature above or below normal, then special materials are added to the concrete at the stage of mixing the mixture. We would like to tell you about such materials in our article.

Causes of concrete cracking

Causes of concrete cracking

There are many reasons for cracking concrete. This can be both the impact of external factors on concrete surfaces, and non-compliance with the rules of working with concrete at the stage of its mixing or pouring.

The first ones include such problems as exposure to moisture, chemicals, temperature changes, carbonation, etc.

The first ones include such problems as exposure to moisture, chemicals, temperature changes, carbonation, etc.

The second ones include: adding too much water to the mixture, using low-quality cement, pouring concrete under unsuitable weather conditions, rapid loss of moisture from concrete after pouring, and so on.

Another problem is the neglect of the use of reinforcing compounds, which are applied both 28 days after pouring concrete (when it gains full strength characteristics), and those compounds that immediately interfere with the concrete mixture. After all, thanks to them, it is possible not only to avoid the appearance of cracks, but in general to strengthen the surface.

What should I add to the concrete mortar so that it does not crack?

What should I add to the concrete mortar so that it does not crack?

Among the main problems when pouring concrete are: insufficient plasticity of the mixture and rapid loss of moisture during drying of concrete.

Because of the first, there is a dangerous desire to increase the volume of water when kneading.

Because of the first, there is a dangerous desire to increase the volume of water when kneading.

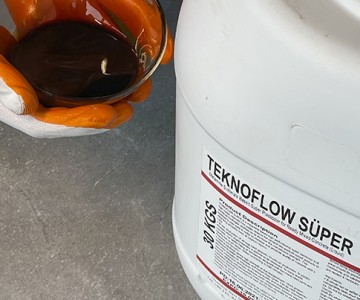

These two problems can be eliminated very simply by adding a plasticizer to the concrete composition, for example, Teknoflow Super. Thanks to this material, there is no need to add more water to the concrete mix, as it increases its fluidity and plasticity. And thanks to this, the strength of concrete increases, thereby making it more durable. Also, the plasticizer allows you to pour concrete at an air temperature below normal. By the way, to obtain such an effect of this material, no more than 2% of the total mass of the concrete mixture is needed.