Pouring concrete is a simple task, but only at first glance. In fact, with improper mixing of the concrete mixture, improper pouring or pouring under unfavorable weather conditions, there is such a phenomenon as the appearance of cracks, with which, it does not take long to wait.

Therefore, in this article we would like to talk in more detail about the causes of cracks so that you do not encounter such problems on your own experience.

Therefore, in this article we would like to talk in more detail about the causes of cracks so that you do not encounter such problems on your own experience.

Reason 1: incorrect ratio of the components of the mixture

Reason 1: incorrect ratio of the components of the mixture

One of the most common reasons is the use of more water than it should be.

This may be due to several reasons:

- ignorance of the rules for mixing concrete mix components;

- adding a larger volume of water to obtain a more fluid texture of the mixture.

Both causes have consequences: obtaining a less durable concrete surface and the formation of cracks.

We conclude that the exact observance of the proportions of the components plays an important role in pouring concrete.

Reason 2: rapid loss of moisture

Reason 2: rapid loss of moisture

It is known that the time of rejection of freshly poured concrete mixture occurs within a month (up to 30 days).

And in order to achieve the correct uniform rejection of it, it is necessary to ensure a sufficient level of moisture. Unfortunately, not everyone pays attention to this point, because of non-compliance with which cracks can appear almost immediately. Especially important are the first 3 days after pouring. In fact, the concrete itself secretes milk, which under normal conditions is sufficient for the proper drying of the concrete mixture, but if the air is too dry or the weather is windy, or the air temperature is high, then the concrete must be additionally moistened with water.

Reason 3: unsuitable weather conditions

Reason 3: unsuitable weather conditions

Like many other building materials, concrete requires suitable weather conditions during pouring.

The ideal conditions are:

the air temperature is about 20 degrees Celsius;

the air temperature is about 20 degrees Celsius;- absence of any precipitation;

- moderate moisture;

- evening or morning time of day.

Naturally, if you wait for the right day to pour concrete, then construction will become a very, very slow process. Therefore, today there are various additives that are mixed into the concrete mixture and poured into it in windy, hot, and cold weather. Such additives are called plasticizers.

Note: During the rain, it is still not worth pouring concrete.

Note: During the rain, it is still not worth pouring concrete.

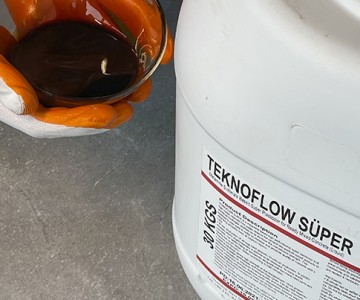

As for the choice of plasticizer, we draw your attention to the high-quality Teknoflow Super material, which is produced on the basis of naphthalene sulfate, increases the plasticity of concrete and significantly affects its quality.