Concrete is considered the most popular building material, but at the same time it requires high responsibility when working with it. These include: a clear ratio of the components of the mixture, proper pouring, high-quality care during solidification, hardening and suitable operating conditions. Together, all these nuances make the reinforced concrete structure very strong, wear-resistant and durable. If you do not take the pouring of concrete very responsibly or do not strengthen it after, then the probability of cracks is 100 out of 100.

In this article we will tell you what to pay attention to when pouring concrete and about the causes of cracks immediately after drying.

What should you pay attention to when pouring concrete?

What should you pay attention to when pouring concrete?

Below we describe 4 important tips when pouring concrete:

It is known that heat negatively affects concrete not only during pouring, but also during its drying, therefore, care should be taken that moisture does not evaporate from the surface too quickly, as this is fraught with the rapid appearance of cracks.

Therefore, if necessary, moisten the concrete additionally, usually with water. Also, freshly laid concrete should be protected from the sun, closing it from direct rays.

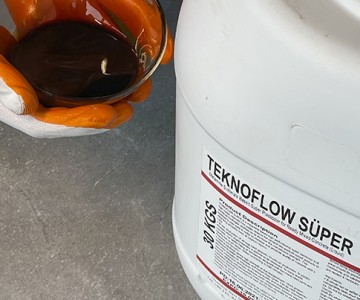

An especially common problem is the addition of an excessive volume of water. Do not add water to the cement mixture already mixed, even if you see that the material is not sufficiently plastic. This will reduce the strength parameters of the future concrete structure and may cause cracks. It is recommended to use a special additive that interferes with the concrete mixture and makes it more fluid, plastic and convenient to work with, but does not reduce its strength characteristics. Such additives are plasticizers and superplasticizers.

This must be done within 3 days after pouring if the surface size is 3 m2 or more. Neglect of this point can lead to the most deplorable consequences for a reinforced concrete structure - its destruction. Since concrete is an inelastic material, therefore, under the influence of various changes in the earth's surface, temperature, etc. it will cover with deep enough cracks.

This must be done within 3 days after pouring if the surface size is 3 m2 or more. Neglect of this point can lead to the most deplorable consequences for a reinforced concrete structure - its destruction. Since concrete is an inelastic material, therefore, under the influence of various changes in the earth's surface, temperature, etc. it will cover with deep enough cracks.

Failure to comply with each of the above points are the reasons why cracks form immediately or almost immediately after pouring concrete. Therefore, follow all the rules for pouring the material and do not forget to further strengthen it after solidification (28-30 days after pouring).