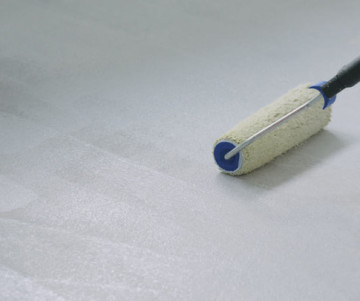

Teknobond 600 TIX epoxy colored coating for textured concrete

Teknobond 600 TIX is a high-quality textured finish color coating based on epoxy resin for concrete bases and surfaces. It creates a strong and non-slip coating, resistant to moisture, abrasion, exposure to various chemicals and acids. It provides reliable protection of the surface from atmospheric phenomena, retains color and shine for a long time both indoors and outdoors.

12546 uah

Teknobond 600 TIX is a high-quality textured finish color coating based on epoxy resin for concrete bases and surfaces. It creates a strong and non-slip coating, resistant to moisture, abrasion, exposure to various chemicals and acids. It provides reliable protection of the surface from atmospheric phenomena, retains color and shine for a long time both indoors and outdoors.

APPLICATION

- For concrete surfaces, cement screeds operated under normal and medium load levels (warehouses and maintenance workshops, assembly areas, loading ramps and parking lots, parking lots, etc.).

- As a finishing coating for floors with increased requirements for slip resistance and easy cleaning.

- As a finishing coating for rooms with constant high humidity.

- As a finishing coating for premises with requirements for creating a hygienic environment (food industry enterprises).

FEATURES / ADVANTAGES

-

Does not contain solvents.

-

Simple to use, easy to apply.

-

For indoor and outdoor use.

-

It has high mechanical resistance.

-

It has high resistance to abrasion, and the movement of mechanical equipment with metal wheels is allowed.

-

Creates a non-slip surface with an "orange peel" texture.

-

It has an easy-to-clean/washable structure, preventing the development of microorganisms on the surface.

MATERIAL INFORMATION

|

Packaging |

20 kg set |

|

Expiration date

|

12 months from date of manufacture, when stored in original undamaged packaging. |

|

Storage conditions

|

Store in unopened and undamaged original packaging in in dry conditions at temperatures from +5 °C to +30 °C. |

|

Color/Type |

RAL |

|

Density |

Ready working mixture: 1.45 ± 0.05 (g/ml) |

TECHNICAL INFORMATION

|

Material base |

Epoxy resin |

|

Mixing proportions |

9 units of component A : 1 unit of component B (by weight) |

|

Mixture life

|

~ 30 min (depending on ambient temperature) |

|

Cost |

~ 0.5 kg/m² |

|

Full curing time |

9 days |

|

Application temperature

|

+5 °C - +30 °C (possible significant increase or decrease in time) drying depending on temperature) |

|

Adhesion

|

To concrete ≥ 4 N/mm² To metal ≥ 3.0 N/mm² |

APPLICATION INSTRUCTIONS

SUBSTRATE QUALITY / PREPARATION

The surface must be free from dust, dirt, loose particles, cement mortar residues, oils, silicones and must be dry. The concrete base must be clean, strong and have sufficient compressive strength (at least 25 N/mm²) and tear strength of at least 1.5 N/mm². Damage, cracks, potholes on the concrete surface must be repaired in advance using appropriate cement (Teknorep/Teknogrout/Teknoself) or epoxy (Teknobond 400D/405D) repair mixtures.

KNEADING

- Add component B to component A.

-

Mix both components with a low-speed electric mixer (maximum 400 rpm) for 2–3 minutes until smooth.

-

It is necessary to mix the material in the amount that you will be able to use, according to the proportion specified by the manufacturer.

CAUSING

Make sure that TEKNOBOND 600 TIX is applied to a solid, thoroughly cleaned and non-porous surface. To strengthen the surface and reduce absorption, use TEKNOBOND 300 primer (in 2 coats).

TEKNOBOND 600 TIX is applied with a "coral" or regular paint roller.

CLEANING THE TOOL

Clean tools and equipment with water immediately after use. Once the material has cured, it can only be removed mechanically.

LIMITATION

-

Do not use at temperatures below the minimum and above the maximum permitted.

-

Low temperatures slow down hardening, high temperatures accelerate it.

-

Crystallization may occur when the material is stored below 0°C for a long time. If the crystals disintegrate when the product is brought to room temperature, the product can be used.

-

Do not add foreign substances to the product.

-

The ratio of components is precisely calculated, do not use less/more of components A or B.

SAFETY MEASURES

The product may cause irritation if it comes into contact with the skin. It is necessary to use work clothes, protective gloves, a mask and glasses. You can also apply a protective cream to your hands before starting work. In case of contact with eyes, immediately rinse your eyes with warm water and consult a doctor.

MATERIAL DATA BASIS

The above technical data are obtained from laboratory tests conducted at a temperature of + 20 °C and a relative humidity of 50% in the Tekno Yapı Kimyasalları laboratory. The results are obtained 28 days after the tests. The actual characteristics of the material may change for reasons beyond our control. Since we are unable to control the installation process and operating conditions, we are only responsible for the quality of the material. The production of materials is periodically optimized and improved, we have the right to make changes to the technical description of the materials without informing the customer.