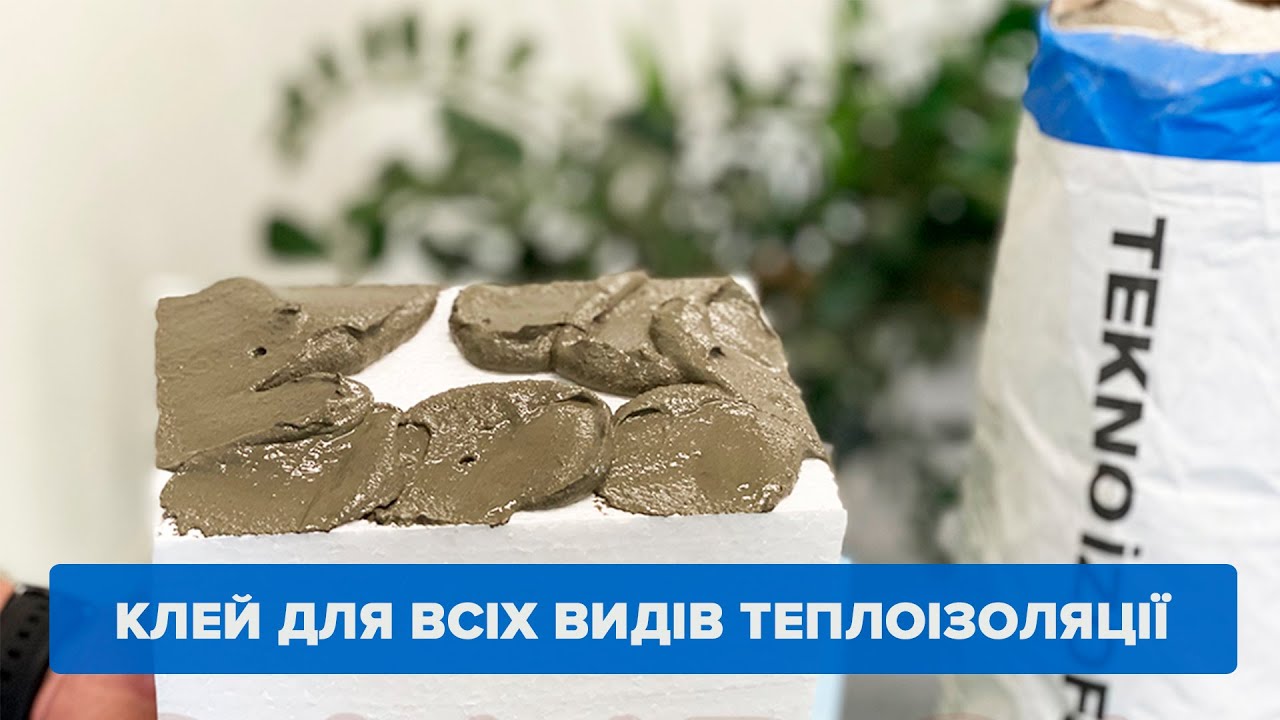

Teknoizofix is a polymer-reinforced adhesive mortar based on cement, which is used for laying thermal insulation boards (EPS, XPS, mineral wool, etc.) on surfaces such as concrete, brick, aerated concrete.

Application areas:

- For indoor and outdoor use on vertical and horizontal surfaces

- For laying thermal insulation boards on any mineral surfaces

- For residential premises, shopping centers, hospitals

- For use as a simple glue

Properties of adhesive:

- Easy to use

- It has a high resistance to any climatic conditions / changes

- Long-lasting

- Non-flammable

- Breathable

| Colour |

Grey |

| Expiration date |

12 months in the closed original packaging |

| Packaging |

25 kg bag |

| Application temperature |

+5 °C - +35 °C |

| The ratio of the components of the compound |

6,0-7,0 water / 25 kg of powder |

| The life time of the compound |

4 hours |

| Commissioning time |

48-72 hours |

| Application thicknes |

≤ 8 mm |

| Dowel laying time |

after 24 hours |

| Adhesion to the material (EN 13494) |

0,12 N/mm2 |

| Adhesion to the substrate (EN 1015-12) |

0,9 N/mm2 |

Consumption table:

| Teknoizofix |

Consumption of powder for expanded polystyrene boards (kg) |

Consumption of poeder for mineral wool slabs (kg) |

Volume of water for mixing (l) |

| 25 kg craft bag |

4-4,5 |

5,5-6,5 |

6,0-7,0 |

- Before applying the material, clean the surface from any types of oil, rust, detergents, dirt and other substances that prevent setting.

- If there are cracks or cavities on the surface – they must be sealed with Teknorep.

- Before laying, the surface should be slightly moistened.

- If there are too many defects on the surface, you should use plaster in advance.

- Glossy surfaces, such as glass mosaics and ceramics, should be primed with Teknolatex 300.

- Painted surfaces should also be pre-primed with Teknolatex 300.

- When working on concrete surfaces, they should be pre-plastered.

- The mortar can be applied in several ways:

- It is used for uneven or old surfaces. The mortar should be applied on all edges of the thermal insulation board with a spatula. Thermal insulation boards should not be laid if the surface is too deformed. In this case, the material may peel off from the surface, returning to its original position.

- It is used for smooth, even surfaces. The mortar should be applied using a notched spatula.

Notes:

- Pour 5,5-6,5 liters of clean water into a clean container. Pour the powder Teknoizofix (25 kg) into a container with water and use a low-speed mixer to knead the compound for at least 5 minutes until a homogeneous mass is obtained. Leave the resulting mortar for 3 minutes, then re-mix it with a mixer for 2 minutes.

- Depending on the weather conditions, the bonding time of the material to the surface is 24-48 hours.

- The work should be at an air temperature of +5 to +35 °C. When laying tiles at a low (below +5 °C) or elevated (above +35 °C) temperature, it is necessary to cover freshly laid bricks or aerated concrete blocks with thermal insulation material.

- After applying the mortar, it is necessary to protect the surface from adverse weather conditions, such as direct sunlight, strong wind, high air temperature (more than +35 °C), rain and frost.

- The tools and equipment used must be washed with warm water immediately after use. You should also wash your hands thoroughly.

- The product may cause irritation if it gets on the skin. It is necessary to use work clothes, protective gloves, a mask and glasses. Before starting work, you can also apply a protective cream on your hands. In case of contact with the eyes, immediately rinse the eyes with warm water and consult a doctor.

1. Which glue is better for thermal insulation?

Cement-based polymer adhesive is used for laying thermal insulation boards. Teknoizofix is considered an excellent option, when using which the input into the exlutation is possible after 48-72 hours.

2. What kind of glue to glue mineral wool?

Mineral wool is recommended to be glued with a special adhesive composition with high resistance to climatic changes. For example, Teknoizofix polymer glue will perfectly cope with the task.

3. What mixture is used for gluing insulation?

For gluing EPS, XPS, mineral wool and other types of thermal insulation materials, it is recommended to use a special non-flammable breathable adhesive mixture reinforced with polymers.

4. What kind of styrofoam glue?

Teknoizofix is an excellent choice for laying thermal insulation boards made of expanded polystyrene. The consumption of the dry mixture is 4-4.5 kg per 1 m2.

25_105_1748004896.png)

_117_1748247133.png)