Concrete is used in the construction of all kinds of buildings: from a small courtyard in the village to large-scale multi-ton buildings, for example, bridges and high-rise buildings. being such a popular building material, concrete has some disadvantages, namely, it is prone to cracking and can crumble. therefore, in order to strengthen and extend the service life, it is recommended to use special additives or hardening mixtures for concrete.

- Dry toppings;

- Liquid toppings or impregnations;

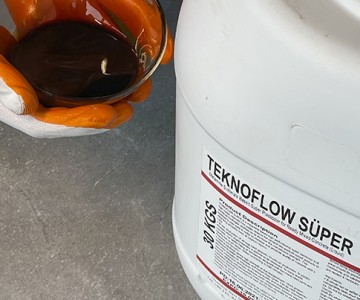

- Plasticizers;

- Epoxy coatings;

- Lucky.

Each of them has its own varieties, fields of application and price range.

For example, whether the concrete is freshly laid or has been in use for some time, whether the concrete surface will be used with a medium degree of operation or with a high degree, whether the surface is in a room with normal operating conditions or with special ones, for example, with constant exposure to chemicals, and so on.

For example, whether the concrete is freshly laid or has been in use for some time, whether the concrete surface will be used with a medium degree of operation or with a high degree, whether the surface is in a room with normal operating conditions or with special ones, for example, with constant exposure to chemicals, and so on.

For example, for a store or a shopping center, you can use either quartz topping or varnish, and for a warehouse it is better to make a stronger coating and use corundum topping or apply two types of hardeners at once: corundum topping and varnish.

Also, when pouring concrete, weather conditions must be taken into account. For example, if there is a strong wind or the air temperature is below or above normal, it is impossible to do without the use of plasticizers.